Military Seats

BattleSafe

BattleSafe delivers on quality and safety

The BattleSafe brand, highly regarded in defence applications, has seats currently in active service overseas, showcasing its well-known reputation.

Our Australian made products comply with military specifications (i.e. flame retardancy, corrosion protection) and can include unique features including mine-blast protection, sideward and rearward facing, wall and roof mounting, closed cell foam, among others. We also offer service support of all our products.

Battle tested and proven

The BattleSafe range, manufactured in Australia, incorporates a wide variety of military seating solutions.

We have supplied to prime contractors and defence forces on various projects including:

- Bushranger (Bushmaster)

- Bushmaster SUK Upgrade

- Land 121 – Light

- Perentie (Land Rover 6×6)

- M113 APC Upgrade

- ASLAV

- HSEV

- ANZAC Class Frigate ASMD Upgrade

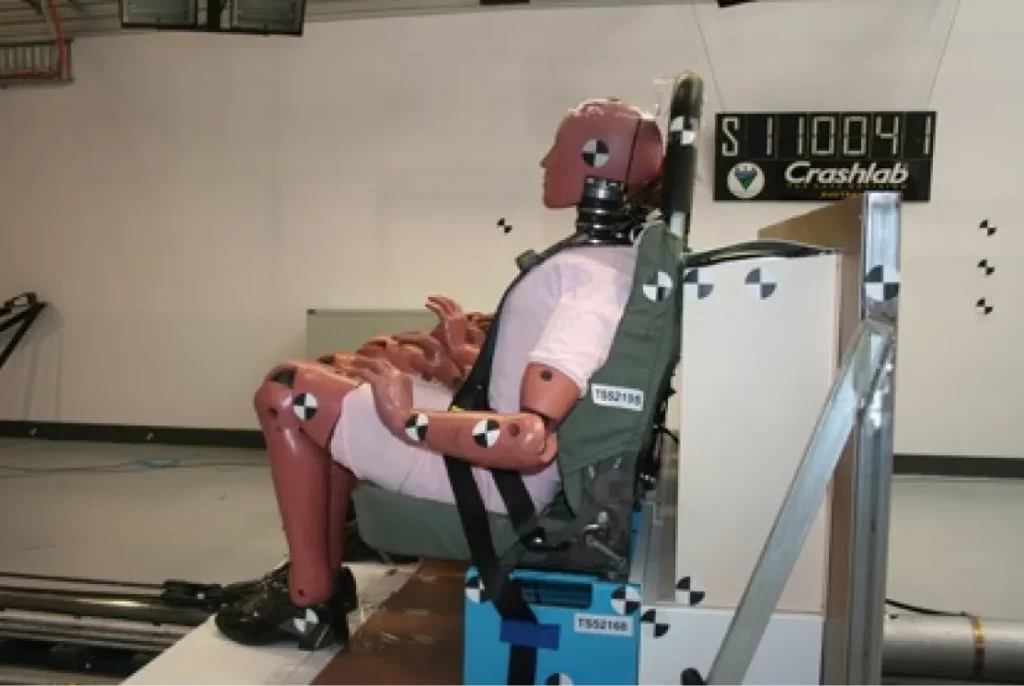

Prototypes undergo strict tests before production

Research has shown that the four main injuries sustained by vehicle occupants in the event of Improvised Explosive Device (IED) attacks include:

- Brain and organ injuries as a result of blast wave-induced changes in atmospheric pressure;

- Injuries sustained from shrapnel and other objects put in motion;

- Injuries sustained by people being forcefully put in motion by the blast;

- Burns or inhalation of gases.

Some of the safety features of the Stratos BattleSafe range include:

- Wall or roof seat mounting to minimise shocks transmitted to user from the vehicle structure;

- Strong metal base plates and optional back plates to prevent shrapnel penetration;

- Sideward lateral support wings and 4-point seat harness to minimise injury to head and neck

- Low burn integral skin moulded components to reduce burn and smoke from seats on fire

- Optional footrest to minimise shocks transmitted to user from the vehicle structure

Quick turn around from prototype to production

Running to a deadline? Stratos' team of engineers and draftsmen work together with production workers to develop prototypes for you to trial at our manufacturing facillities in Australia.

Our facility is equipped for in-house testing, including pull and drop tests. For other assessments, such as sled testing, we utilise external facilities nearby. Once a prototype is tested and ready, manufacturing commences to align with your production schedule.